We thought we would inaugurate the section “Sherman VVSS (Vertical Volute Spring Suspension) Bogie series” dedicated to the various components produced by multiple foundries that went to make up the Sherman rolling train (edited by Fabio Sacchi and Fabio Mosca)

VVSS Boogies: Sherman Suspensions in World War II.

The M4 Sherman tank is one of the most iconic armored vehicles of World War II. Produced in tens of thousands by the United States and used by all the Allies, the Sherman was known for its mechanical reliability, ease of manufacture, and adaptability. A key technical element that influenced the wagon's performance in the field was the suspension system. In particular, the VVSS (Vertical Volute Spring Suspension) suspension, based on a design known as a “boogie,” was used in early models.

What is VVSS?

The acronym VVSS stands for Vertical Volute Spring Suspension. It was a relatively simple and robust system designed to absorb the shocks of rough terrain and provide good mobility for armored vehicles.

Each side of the Sherman tank mounted three double bogies (boogies), each of which contained two load-bearing wheels connected by an internal suspension. Each boogie was equipped with a pair of spiral coil springs (volutes) mounted vertically, hence the name of the system.

Operation of the VVSS Boogie

Each boogie was an independent module that could be removed and replaced with relative ease, facilitating maintenance in the field. The structure included:

Two load-bearing wheels (road wheels)

A load-bearing structure that served as the boogie's frame

Two vertical volute springs, inserted within the structure

A swinging arm connected to the wheels that moved up and down by compressing the springs

When the wagon encountered an obstacle, the upward movement of the wheels caused the vertical springs to compress, absorbing energy and reducing shock transfer to the crew and hull.

The great American productive machine

The United States produced over 49,000 Shermans during World War II. Each Sherman with VVSS suspension had 6 boogies (3 on each side) → a total of nearly 300,000 boogie units required. This huge requirement made it impossible to outsource production to one company or foundry a process of standardization of components and speed and logistics became necessary, which can be summarized as follows:

- VVSS boogies were designed to unified specifications by the Ordnance Department.

- This meant that different foundries could produce the same component, ensuring compatibility and interchangeability.

- The concept was “any part must fit on any wagon,” regardless of who produced it.More manufacturers meant faster deliveries to the wagon assembly factories (Detroit Arsenal, Fisher Body, Pressed Steel Car,

- etc.).

- Local foundries could supply the nearest production lines, shortening transportation time and reducing costs.

From reality to model...

Given the particular differences that exist between one foundry and another, we have come up with 6 different boogie patterns that will cover almost all of your sherman, characterizing them to the fullest and making them extremely realistic and relevant to reality. Below we also provide a diagram that will help you choose the most appropriate boogie for your sherman.

That said, let us analyze the six kits:

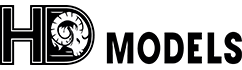

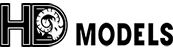

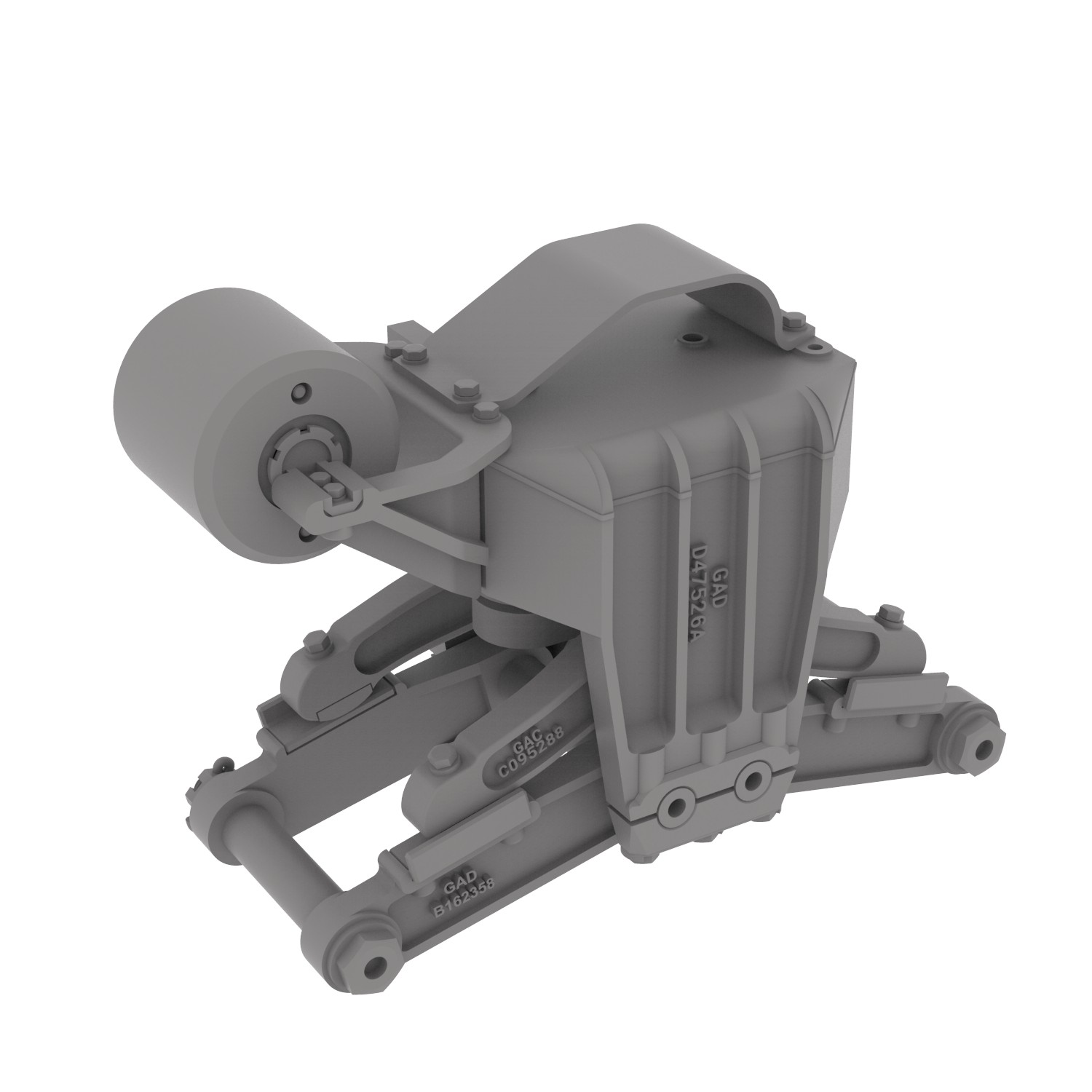

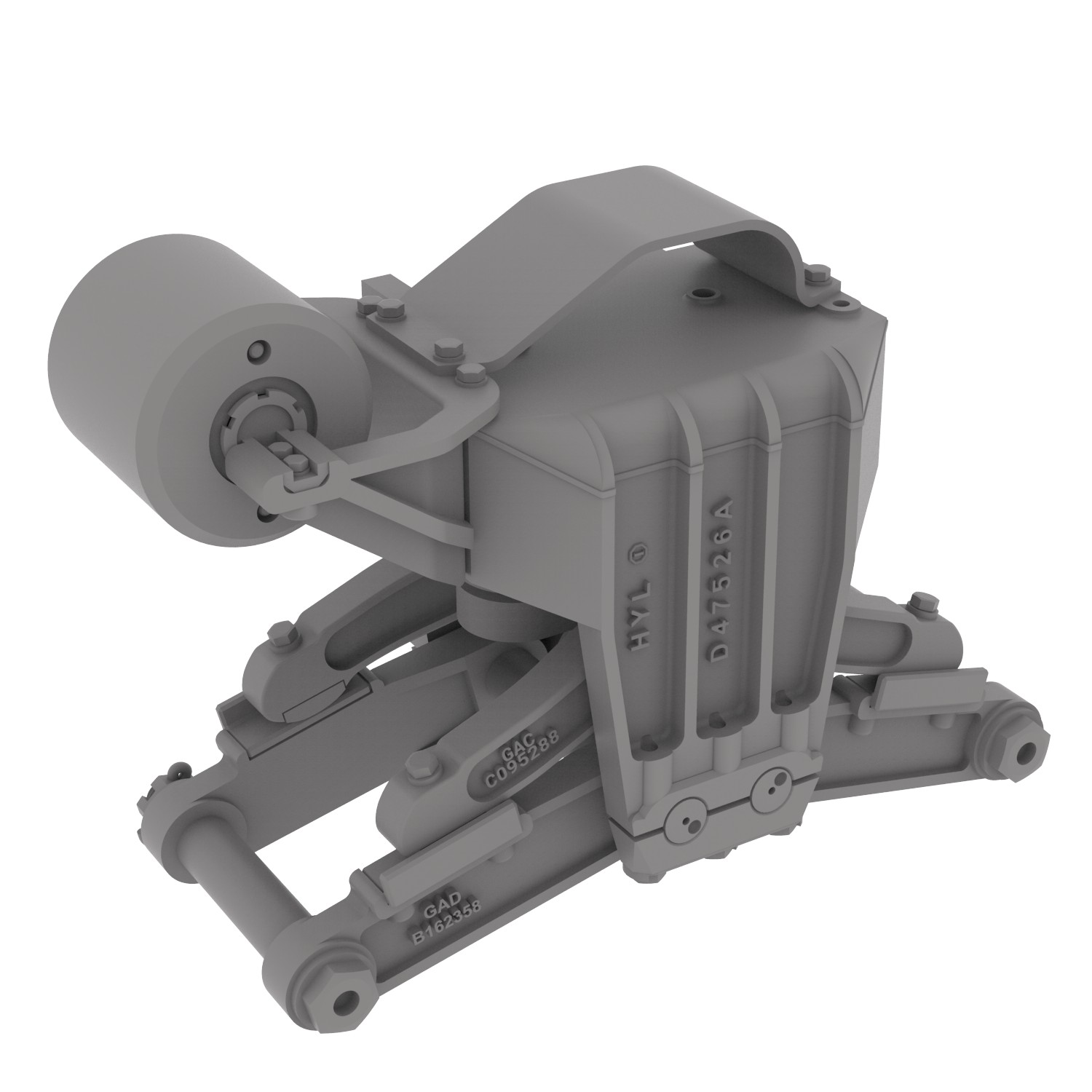

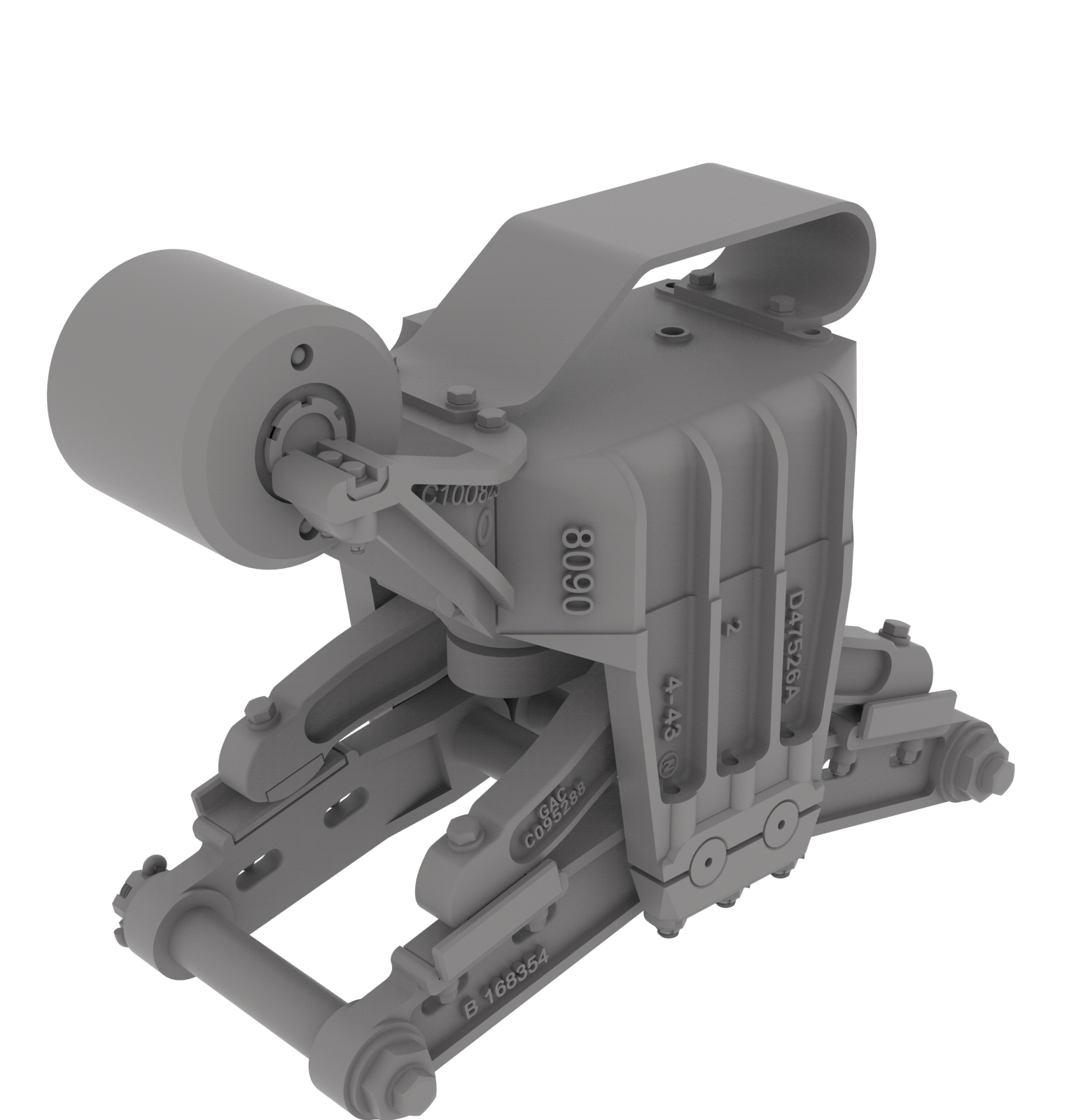

Early VVSS Bogie - Ford Foundry (GAD)

Mounted standard on the M4A3 small hatch produced by Ford. Because the entire production was acquired by the Department of Defense, which sorted them to the factories that needed them, these trucks can also be found on the M4A2 small hatch produced by Fisher

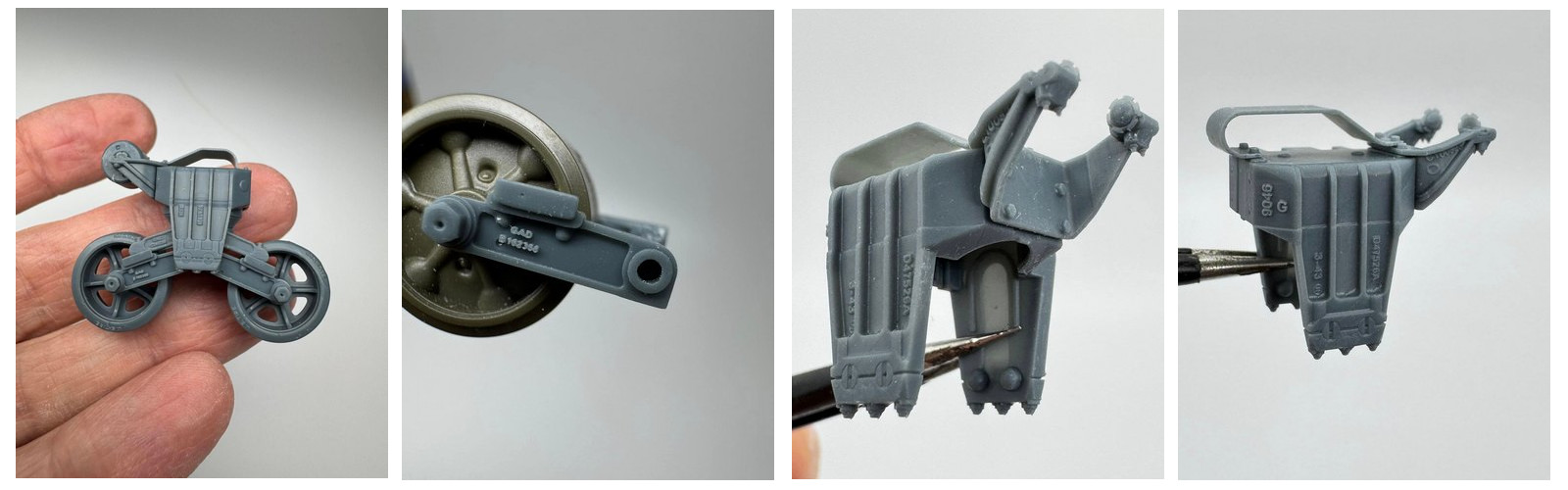

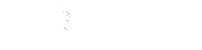

Early VVSS Bogie - National Malleable and Steel Casting

used mostly by Chrysler and are common on the M4A4, M4(105) and M4A3(76)W, of course the latter two in mid/late variants. Also seen in photos of PSC M4A1(76)W

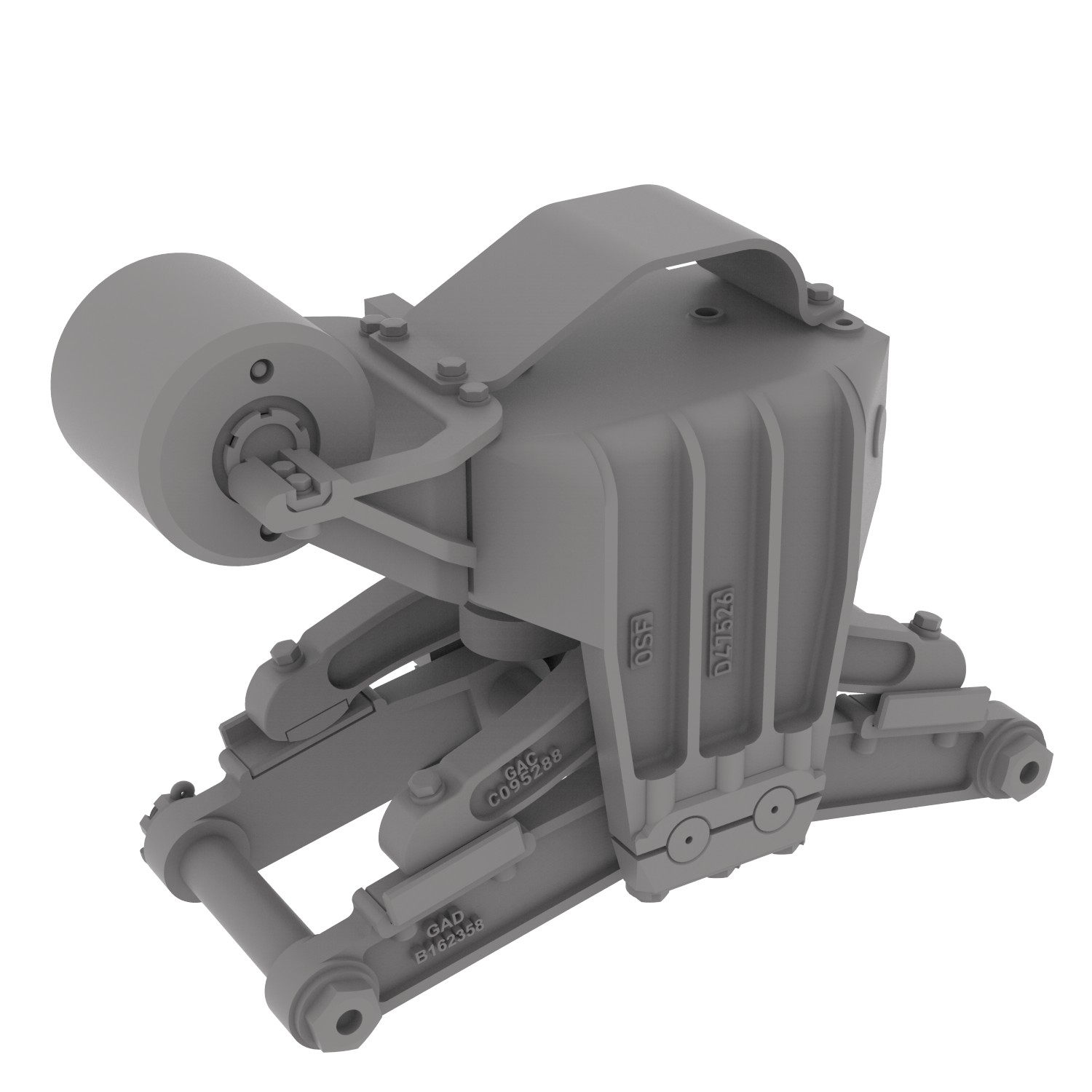

Late VVSS Bogie -National Malleable Cast Variation type A,

are universal, we find them mounted practically everywhere

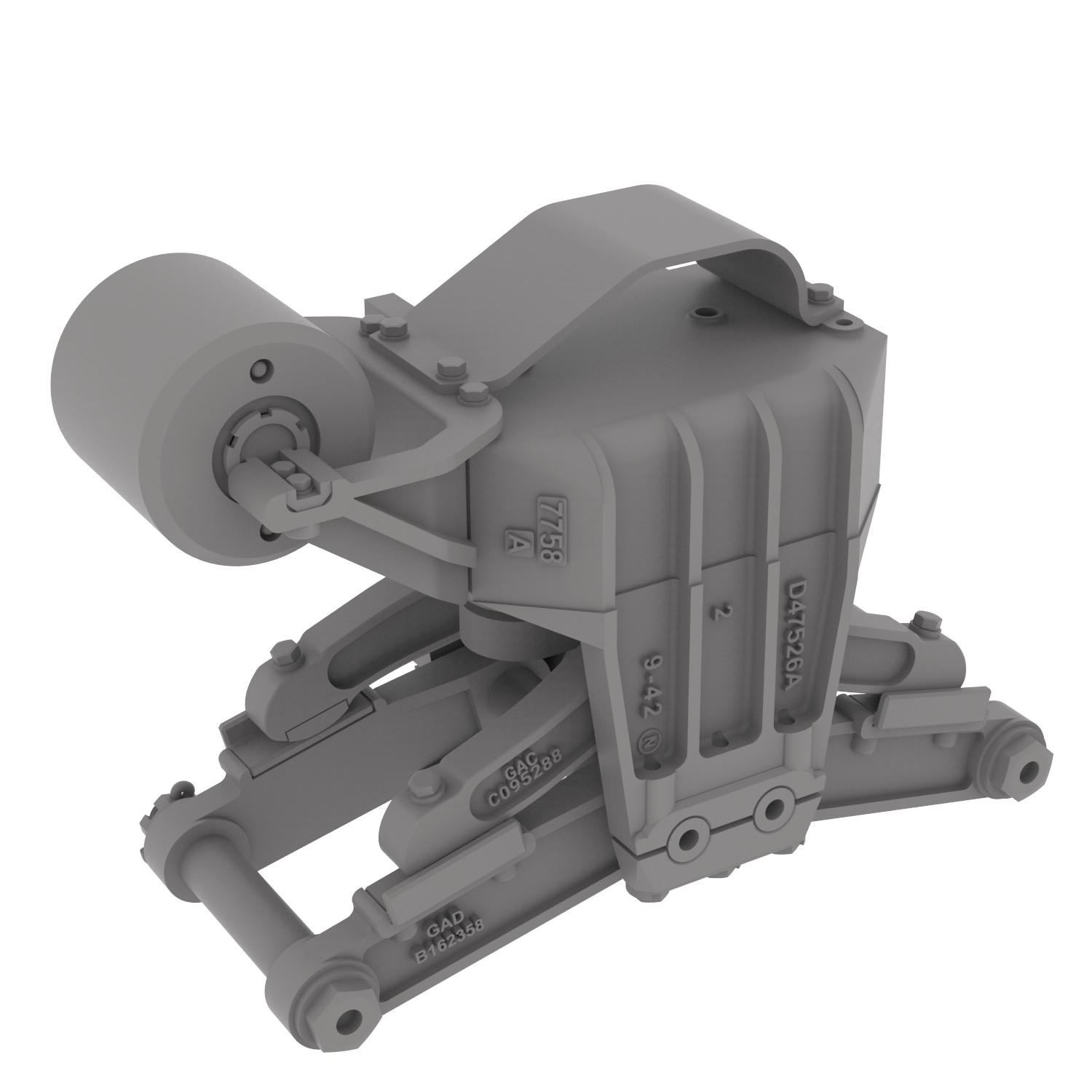

Early VVSS Bogie - Ordinance Steel Foundry (OSF)

Mounted on M4 Baldwin/Pressed Steel, M4A1 PFC/Lima, M4A2 Pullman, ALCO and M4A1 (Grizzly) Montreal Locomotive Works in the Mid variant

Early VVSS Bogie - American Steel Foundries Indiana Harbour Works

Seen in photos on M4 Baldwin/Pressed Steel M4A1 PFC/Lima M4A2 Pullman, ALCO and M4A1 (Grizzly) Montreal Locomotive Works in the Mid variant.

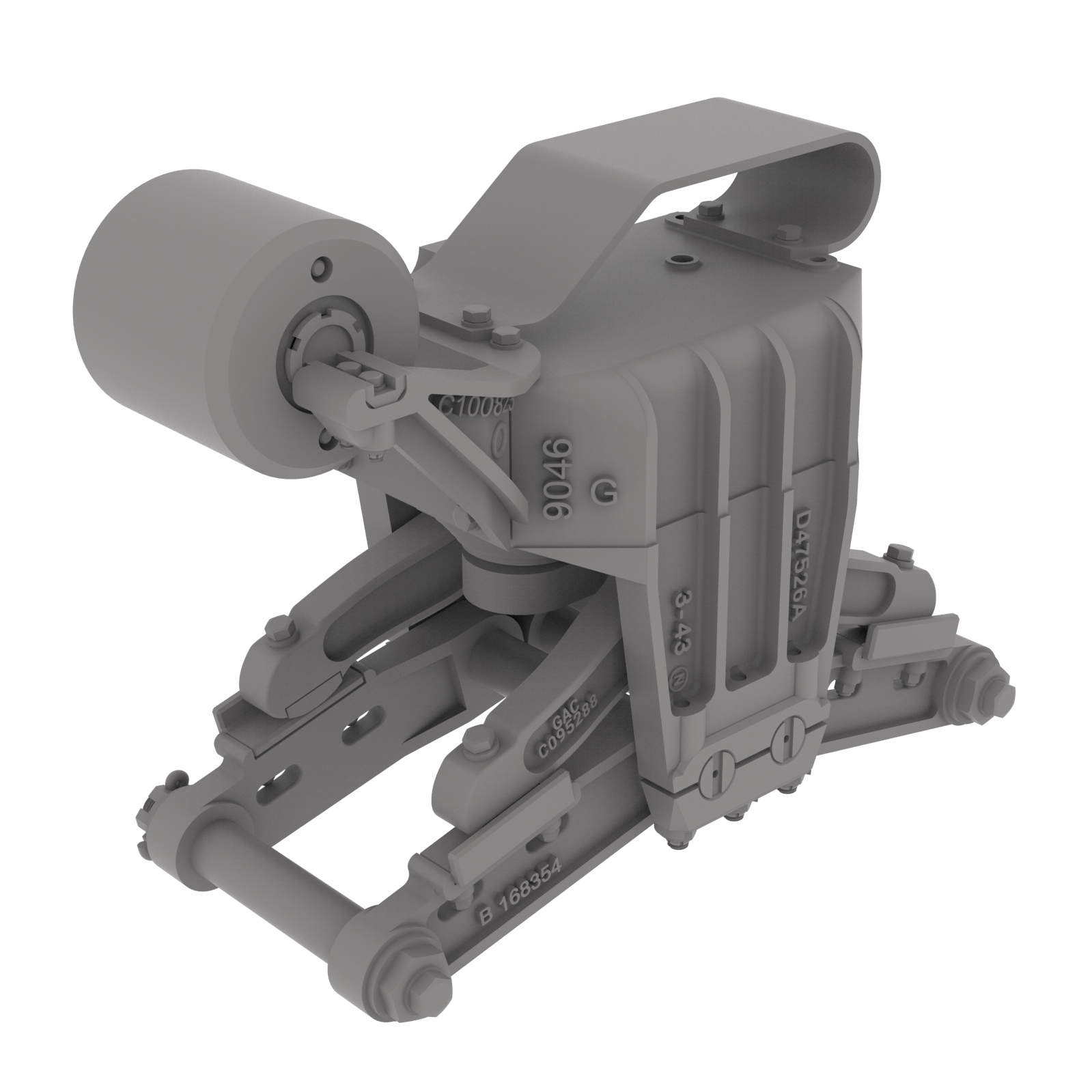

Late VVSS Bogie -National Malleable Cast Variation type B

are universal, we find them mounted practically everywhere